Built by Automation Engineers, for Automation Engineers

After two decades of designing, installing, programming, and maintaining industrial robotic systems, we kept encountering the same frustrating problem: manufacturers desperately needed proper oversight of their automation, but the solutions simply didn’t exist at the right price point.

The Problem We Saw Every Day

Traditional SCADA systems cost £10,000-£100,000+ to deploy – completely out of reach for the SME manufacturers who needed monitoring most. These systems required dedicated hardware, complex installations, and ongoing specialist support that smaller operations couldn’t justify.

Vendor lock-in was killing flexibility. Every robot manufacturer, PLC supplier, and control system vendor wanted to trap customers in their proprietary monitoring ecosystem. Mixing ABB robots with Siemens PLCs and Fanuc controllers meant three separate monitoring interfaces – if you could get them to talk at all.

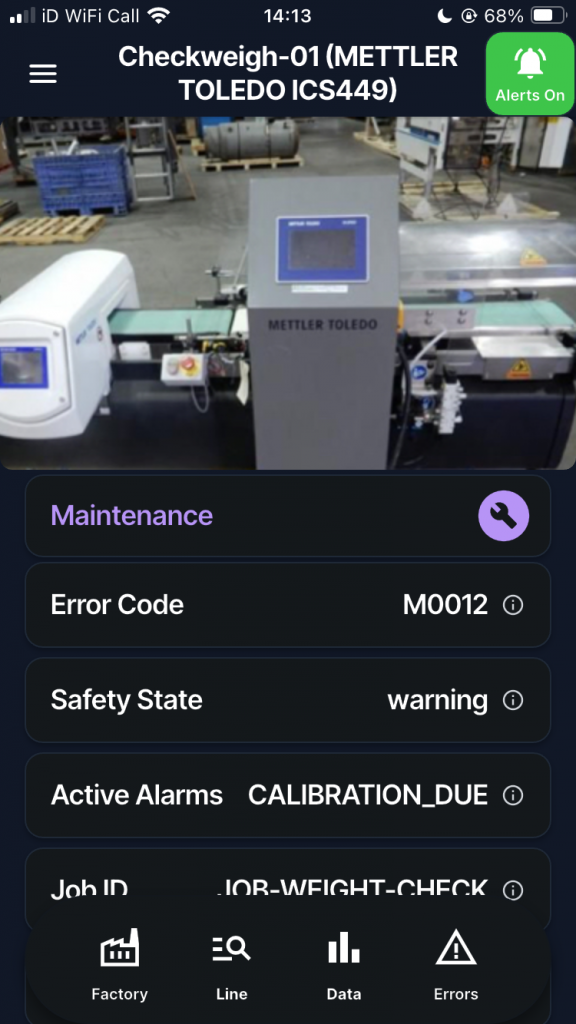

The “set it and forget it” mentality was costing fortunes. We watched countless production lines fail because operators had no early warning systems. A bearing wearing out, a sensor drifting, or a program getting corrupted would shut down entire cells for hours or days. Getting the best out of lines was often guesswork.

What We Learned the Hard way

Through hundreds of automation projects, from automotive assembly lines to pharmaceutical packaging, we discovered that the monitoring problem wasn’t technical – it was economic and architectural.

The technology now existed. OPC UA provided vendor-neutral communication. Cloud infrastructure could handle the data processing. Everyone is used to having and using a smartphone to monitor and assist in almost every aspect of their life from shopping to fitness. But nobody was combining these into an affordable, deployable solution for real manufacturing environments.

That’s why we built RoboVigil.

Our Solution: Vendor-Agnostic Intelligence

RoboVigil takes a fundamentally different approach. Instead of trying to replace your existing control systems or forcing you into another proprietary ecosystem, we work with what you already have.

The Technical Architecture That Actually Works

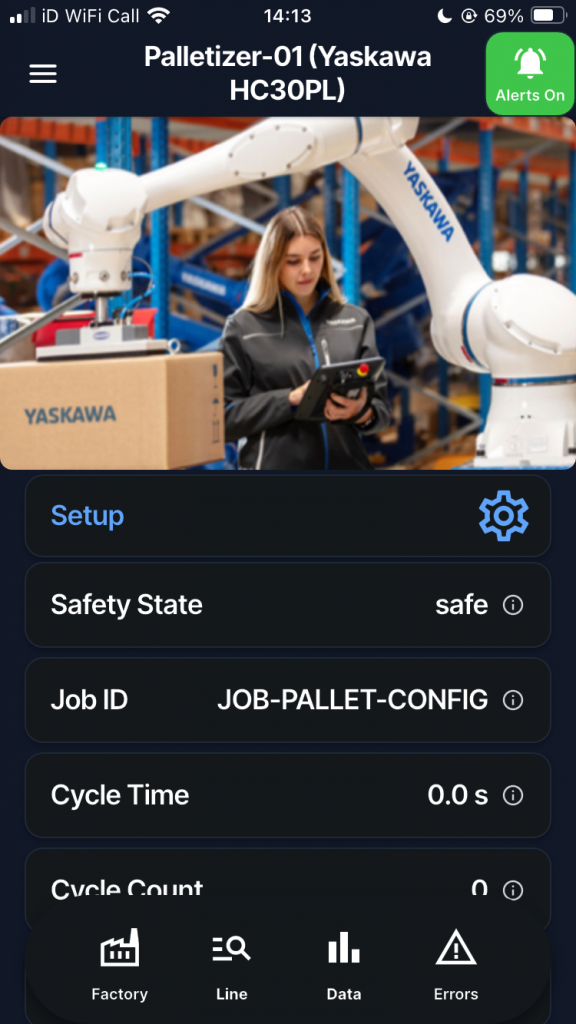

OPC UA as the Foundation We built RoboVigil around OPC UA – the industrial standard that finally delivers on the promise of vendor-neutral communication. Whether you’re running ABB robots, Siemens PLCs, Fanuc controllers, or a mix of everything, OPC UA lets us speak their language without vendor lock-in.

Cloud-Native, Not Cloud-Washed This isn’t your traditional SCADA system awkwardly bolted onto cloud infrastructure. RoboVigil was designed from day one as a cloud-native platform. This means automatic scaling, built-in redundancy, and updates that don’t require downtime or site visits.

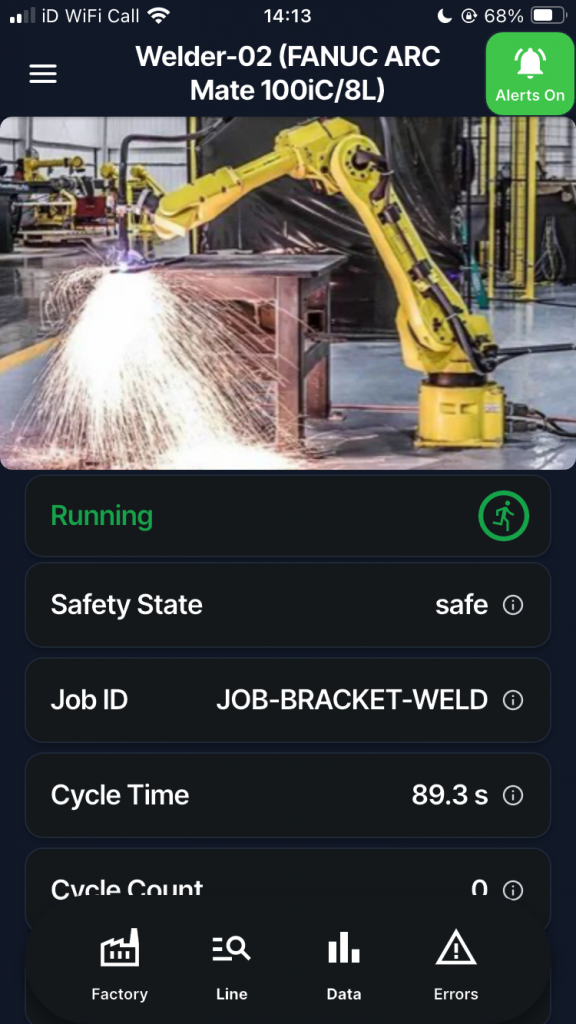

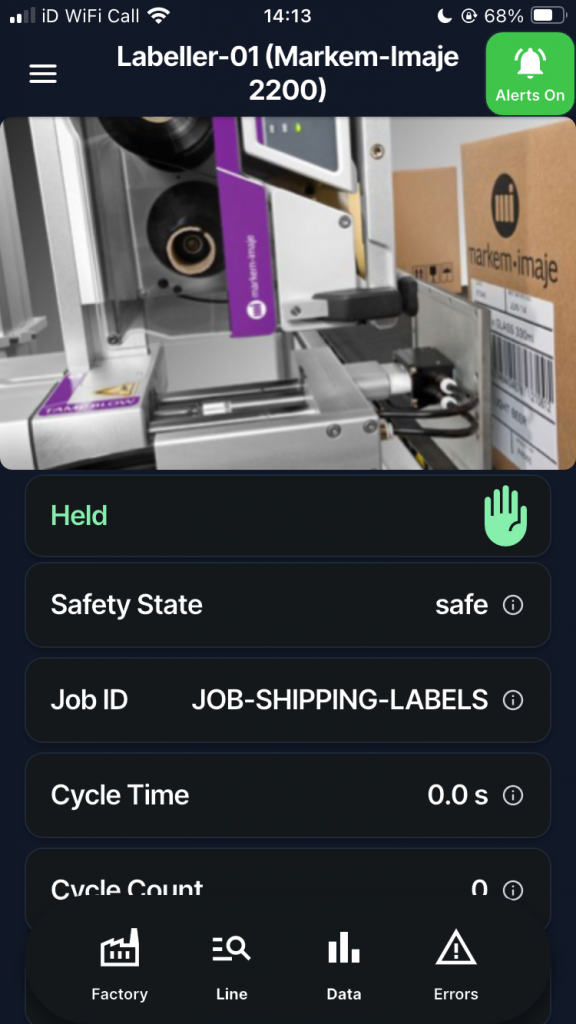

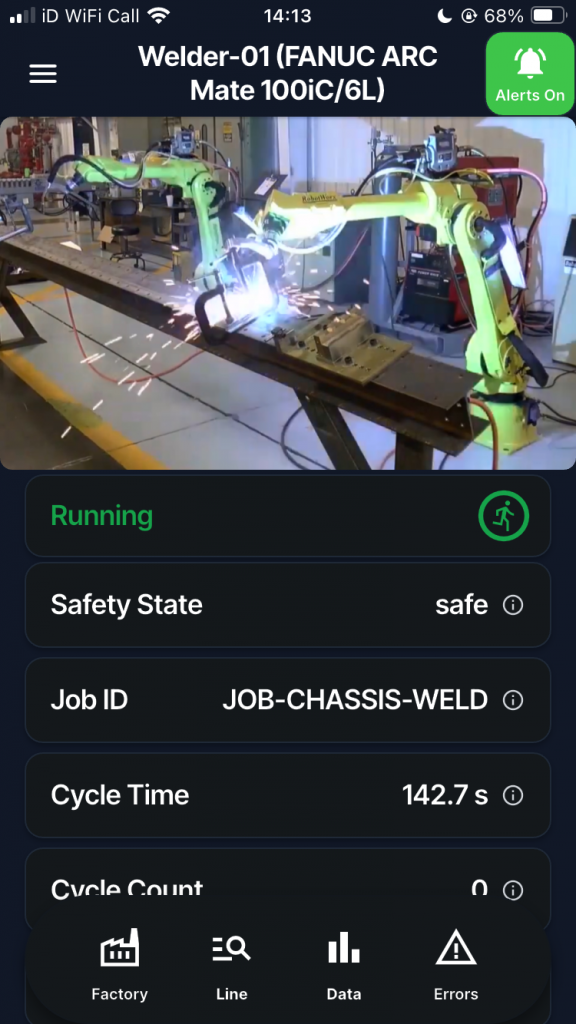

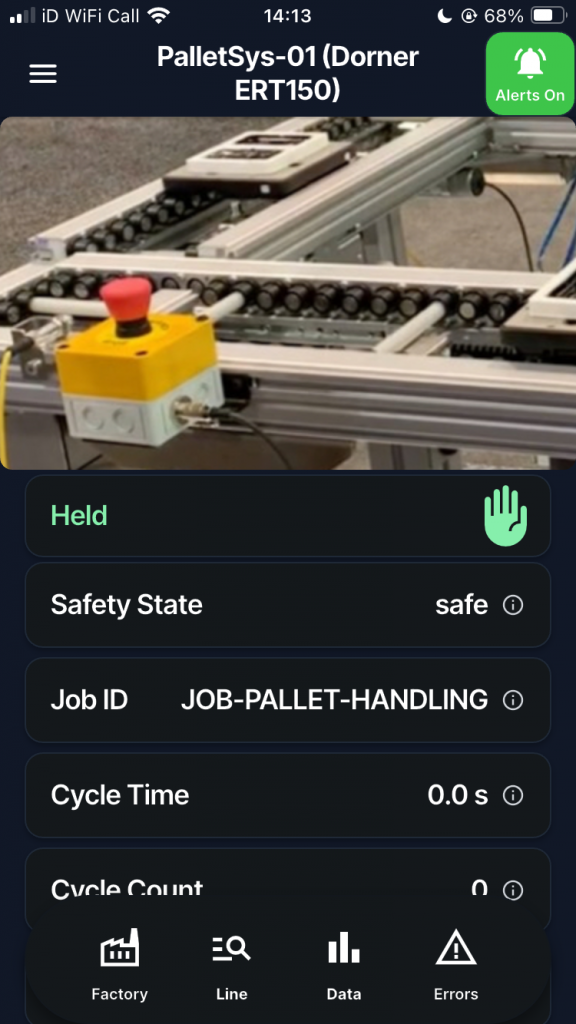

Phone First Approach Having dedicated staff sat monitoring processes is something few SME’s can afford. Having SCADA interfaces in an office and not on the shop floor makes communication difficult at best. Now everyone who needs it can have direct access and information on every machine. Visually, statistically and immediately.

Why This Approach Changes Everything

Deploy in Hours, Not Months No ripping out existing systems. No expensive hardware installations. No armies of integration specialists. If your equipment supports OPC UA (and most modern industrial equipment does), RoboVigil can be monitoring your operations within minutes.

Start Small, Scale Smart Monitor one critical machine for £150/month, then expand as you see value. No massive upfront commitments. No minimum seat licences. No complex pricing calculations based on data points or user counts.

Linked Cameras Give Insights Having real time video feeds linked to machines AND alert triggered pictures gives you immediate insight and context. Combining vision with data tells you far more than either alone.

Built on Real Automation Experience

Every feature in RoboVigil comes from actual problems we’ve encountered in real manufacturing environments. The alert prioritisation system exists because we’ve been woken up at 3 AM by false alarms. The camera integration works seamlessly because we know what operators actually need to see when something goes wrong.

This isn’t theoretical software built by people who’ve never worked on a factory floor. It’s the monitoring system we wished existed during two decades of automation projects.

Why Now: The Right Technology at the Right Price

Industrial monitoring is finally accessible. The combination of mature cloud infrastructure, secure data transmission, and standardised industrial protocols has created an opportunity that simply didn’t exist five years ago.

Secure Data Movement Changes Everything

Modern encryption makes remote monitoring safe. Industrial data can now be transmitted securely over standard internet connections without compromising operational security. TLS encryption and VPN tunnelling mean sensitive production information stays protected whilst enabling remote oversight.

Cloud infrastructure has proven itself in industrial applications. Major cloud providers now offer the reliability, uptime guarantees, and compliance certifications that manufacturing environments require. The days of “cloud isn’t secure enough for our factory” are over.

Bandwidth costs have plummeted. The data streams needed for effective monitoring – machine states, sensor readings, camera feeds – can now be transmitted cost-effectively. What used to require expensive dedicated lines can run over standard business broadband.

The Economics Have Shifted

Traditional SCADA implementations remain prohibitively expensive. While the underlying technology exists, the cost of deployment, customisation, and maintenance puts comprehensive monitoring out of reach for most manufacturers.

Software-as-a-Service has matured for industrial applications. The subscription model that transformed business software is now ready for manufacturing. This means predictable costs, automatic updates, and no large capital expenditure.

OPC UA standardisation reduces integration complexity. What used to require custom programming for each equipment type now works through standardised protocols. This dramatically reduces deployment time and cost.

Why RoboVigil Exists Now

The technical pieces finally work together reliably. Secure data transmission, cloud processing, and standardised industrial communication protocols have reached the maturity needed for production deployment.

The business model makes sense for everyone. Manufacturers get enterprise-grade monitoring without enterprise prices. We get predictable recurring revenue that supports ongoing development and support.

The gap between what’s needed and what’s available has never been larger. Manufacturers know they need better oversight, but existing solutions remain too expensive or complex for widespread adoption.

The technology exists. The business case is clear. The only question is; are you ready?